Have you ever had a lucky die; one that always seemed to roll great? Or one that just never seemed to roll high numbers? Or a game you just couldn't win because the rolls never seemed to go your way? These are examples of how unbalanced dice affect game-play.

Achieving unbiased, unpredictable, and, thus, proper randomization is a critical part of game theory. In terms of board games this means random numbers, random sequences, and unpredictable outcomes. As far back as the 2nd millennium BC, games have used dice to add an element of randomness, and if they don't function properly, your game-play will be affected. I'm here to tell you that nearly every die you own isn't truly random and it's because of how they were manufactured.

If you truly want a pure gaming experience, then read on and consider replacing your dice.

The perfect die isn't the coolest looking, luckiest, or the most expensive. The perfect die is one that grants you equal access to all of its faces when rolled. This means it has exact symmetry of its faces, vertices (edges), and density throughout its body. Most dice included with board games, however, do not meet these basic standards and thus do not grant you equal access to all of their faces. For reasons described below, they are inclined to favor certain faces and fail to provide random numbers.

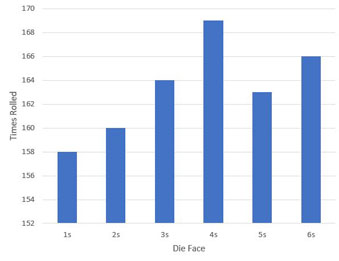

My copy of Grand Austria Hotel (2015) came with 14 dice that were so clearly off that I actually tested them. I rolled them hundreds of times and logged the results. And, indeed, they rolled far more 6s than 1s (1 and 6 are on opposite faces on a D6). In a Grand Austria Hotel game, that means strudel/cake (requiring 1s) was scarce while the wild card action (requiring 6s) was more available than the law of averages would have dictated. If a player had cards giving additional benefits to the 6 action, then they would have an unfair advantage because of the increased frequency of 6s. [My wife once destoryed me with this strategy; she still maintains it was a "good" win :) ]

So why are all of your dice imperfect? It's because of how they are manufactured. Louis Zocchi of Gamescience explains in this 20 minute video from 2008. While it has a lot of good information about dice manufacturing, it also has a lot of sour grapes and bad puns. If you only want the facts, skip it and continue reading below.

The are three main methods of manufacturing dice: injection-mold casting, compression molding, and machining. The vast majority of dice you own are injection-mold cast; probably all of them. Machined dice are more difficult to manufacture and game publishers don't want to spend the money on them. The vast majority aftermarket and custom dice are cast, too.

Machined dice start as large plastic sheets that are then cut into rough cubes. Those cubes are then machined by hand into perfect cubes of very precise specifications. Casino dice are machined to be within 1/5,000th of an inch of 3/4ths of an inch on each side. Some manufactures even produce dice within a tolerance of 1/10,000ths of an inch.

The pips are then drilled out and filled in with colored epoxy that has the exact same density as the plastic. This way the die is very uniform in weight and density. Finally, each die is numbered for tracking purposes and packaged. As you can imagine, this is a labor intensive and costly process.

The end result is dice that are very balanced, have very sharp vertices (edges and corners) and will roll evenly. However, as near perfectly random as these dice are, I can't think of a single board game that includes dice of this quality.

There are also companies, such as GravityDice, who manufacture dice out of metal, usually aluminum or zinc, using a CNC machine. I'm not sure what they mean by "aerospace tolerances", but they claim that the way they drill their pips results in perfectly balanced dice. However, as cool as anodized aluminum dice look and as balanced as they may be, they are quite expensive and if you need 10 or more dice then you are going to be spending a lot of money.

Nearly all dice included with board games are injection-mold cast. This process has a few more steps, but they are largely automated making the process easier, cheaper, and faster. All casting starts with a mold which is usually made of two parts that sandwich together. Inside is one or more die-shaped cavities with channels running between them. Mass manufacturing molds will produce as many as 24 dice per mold.

During casting hot, molten resin, plastic or metal is injected with pressure into the mold. It is forced down the channels into the die-shaped cavities until everything is completely filled. After it cools, the mold is removed leaving the dice connected to a tube-like structure called the "casting rudder". This is the same process that plastic airplane models and plastic figurines are manufactured.

Have you ever had to twist parts for a model airplane off the casting rudder? Dice have to be removed from it as well. But instead of twisting back and forth until it pops off, dice are clipped off of the rudder with what look like wire cutters. This clipping leaves a small nub on the die called a "sprue".

The clipped dice are put into a tumbler (think industrial rock polisher) along with a course, gritty medium and are tumbled until all of the sprues are gone. This process also removes the vertices (i.e. rounds the edges and corners). Next the pips/numbers/symbols, which are cast as depressions in the die's faces, are painted. To do this, the dice are put in a basket and completely submerged in paint. This covers the entire die with paint, not just the depressions.

After the paint is dry, they are put back in the tumbler to remove the excess paint from the faces. Because the pips/numbers/symbols are depressed into the face, the paint will remain in them while the faces have the paint rubbed off. One thing a lot of people don't know is injected-molded dice have additional markings on them assist in manufacturing. These markings are in the form of indented lines along the original edges that are meant to be removed during this second tumbling. The operator will tumble the dice until he can take a sample out and make sure that all of the lines are gone on every die. If he spots any lines, he continues to tumble the batch. This further rounds the vertices and abrades the faces as well. At the end of this 2nd tumbling, the dice will have the excess paint removed, but will also have scars and scratches all over them.

Thus, the dice go back into the tumbler a 3rd time, but this time with a fine-grit medium to polish them. This results in the glossy dice with rounded corners and edges that consumers are accustomed to seeing.

Compression Molding is a process similar to injection molding; both use 2-part molds and heat. Where the injection molding process squirts liquid material into the mold, the compression molding process starts with solid material, called the "charge", already in the mold when it's closed. The mold is then heated and the charge melts into the spaces. There is no rudder, but there will be excess charge that is forced into the mold's seam that must be removed. Some games such as Dragon Dice use it to create interesting effects, but it is not a common method for manufacturing dice. Compression molded dice are usually tumbled, too.

There is a reason that the law requires casino dice have uniform, sharp, and crisp edges and corners.These features cause the dice to have a uniform amount of energy as they roll across the table. Cheats will trim a very small amount, only 1/1000th inch is enough, off the edges where they want the dice to continue its motion thus causing the die to favor one of its sides. If you were to hold two of these modified dice together, you would see a tiny seam between the two where the edges have been altered. This is why you see people inspecting casino dice by holding them together; they are looking and feeling for a seam between the faces. The combined surface between 2 casino dice should be perfectly smooth.

The tumbling process does this rounding but on a massive scale. And even worse, it does it randomly. Not only are the vertices reduced, they are done so at uneven rates. This causes the dice to be very slightly rectangular or egg shaped instead of cubes. What this means is, when rolled, these dice will following the laws of physics and will try to settle with their center of gravity at the lowest point, like an egg rolling onto its side or a cereal box falling over.

If you take twenty tumbled D20s from the same manufacturer and stack 10 of them with 1s facing 20s, then take the other 10 and stake them with 9s facing 12s. You will find that the 2 stacks don't reach the same height. In short, they are elongated (or egg shaped) where they should have equal proportions.

Further, if you rolled dice with crisp, sharp vertices, it will flop a couple of times, then stop, which is visually unsatisfying. Rounded die will roll around in your tray nicely giving the illusion it is getting things randomized for you, but in reality, it's doing the opposite. And while all of that rolling around is visually appealing, you don't actually want your dice doing that. Why? Because if the die isn't symmetrical and balanced, all of that motion is going to allow it to settle with its center of gravity down. Like an egg always rolling on to its side, an asymmetrical die will favor one or two faces.

In general, the more rounded the edges and corners are, the more likely they will be unfair. But if you want proof, here are a few things to check to determine if your dice are garbage or not.

First, you can use a digital caliper to measure each dimension to see if they are perfectly equal. All three dimensions should be exactly the same. Any variance greater than 0.02mm will cause problems.

When I did this with my 14 Grand Austria Hotel dice, the difference between the longest and the shortest dimensions was 0.2 inches, which is egregious. As a point of comparison, because casino dice are machined to 1/5000th inch tolerance, 1,000 of them stacked would have a cumulative difference less than that.

If you don't have a fancy caliper, then you can use the stack method to determine symmetry, but it really only works if you have 10 or more dice. Line up your dice against a ruler making sure they are all in the same orientation and mark the measurement. Rotate the dice 90 degrees clockwise and remeasure. The measurements should be exactly the same. Do this again using the third orientation. If all three measurements don't match exactly, then your dice are not symmetrical.

If you don't have a fancy caliper, then you can use the stack method to determine symmetry, but it really only works if you have 10 or more dice. Line up your dice against a ruler making sure they are all in the same orientation and mark the measurement. Rotate the dice 90 degrees clockwise and remeasure. The measurements should be exactly the same. Do this again using the third orientation. If all three measurements don't match exactly, then your dice are not symmetrical.

Also, check that the faces of your dice are perfectly flat. Do so by taking two of your dice and holding their faces flat against each other. There should be no wobble at all. If they do wobble, this means the faces are not perfectly flat and, instead, are slightly rounded. This will cause your dice to continue their motion when they otherwise wouldn't.

Uniform density is also important. Dice containing fillers such as glitter or metal flakes are likely to be unbalanced because of the difference in density between the die's plastic and the filler. Unless the introduced materials are exactly the same density as the die material, they will definitely be unbalanced and unfair. For example, glitter settling at the bottom of the die mold as it cools will cause too much glitter to be near one corner making it heavier than the other corners. Also, dice made out of wood will be inherently unbalanced due to density variations wood. Ideally, you want your dice to be one type of plastic (i.e. no swirls) with no fillers or inclusions.

You can check your dice for density issues by using the float test. This video does a great job of explaining how to do it.

If you want to use your rounded dice, inspect the faces and numbers carefully. You can sometimes spot manufacturing defects that indicate imbalance. Dice intended to be tumbled will have extra markings on their faces fresh out of the casting mold. One or more of the faces will have a line alone their edges (this is not the line under a 6 or 9 to indicate their value). This line is expected to be removed during the tumbling process. It allows the guy running the tumbler to determine if the dice have been tumbled enough. If you see any of these residual lines on your dice, they are not symmetrical.

Likewise, if you inspect each of the numbers on your die and you see any part of the number missing, you can assume the die is not fair. This is common on D20 dice where the hook on the 2 of the 20 is missing. Sometimes the bottom of the 2 is missing. Either of these issues indicate the die has been polished in a way that the faces are not uniform. A die is more likely to rest on one of its larger faces than on one of its smaller faces.

Should you replace your dice? If you are serious about fairness in your games, I say yes. You don't have replace all of them (more on that later), so don't be overwhelmed. If you are a causal gamer and don't care if there are minor advantages or disadvantages caused by unfair dice, then I say it's not worth your money.

If you decide to replace your dice, I do not recommendation machined casino dice for several reasons. First, they are more expensive and if you need a number of them it can get costly. Second, despite being higher quality in terms of balance, their durability is much lower than quality cast dice. Casino dice are played on felt-top tables and replaced often in a casino setting. Rolling them on your table top will quickly chip the crisp edges rendering them unbalanced. Finally, they only come in D6 and sometimes you need other shaped dice.

Instead, I recommend investing in a set of precision, cast dice made with high quality plastic/resin. I also recommend buying dice that are made of a single type of plastic which is clear. Opaque plastic dice will hide inclusions and other manufacturing issues.

Ideally you will want untumbled dice; ones that have been clipped from the cast and only very slightly cleaned up. If you want the pips/numbers painted, make sure they are hand painted. Remember that clipping the dice off the rudder will leave a small "blemish" on one corner of the die in the form of a small crevice. Zocchi contends that this blemish does not effect the rolling of the die; it is simply a visual blemish. If you stack a set of dice blemish-to-blemish, then restack it with no blemishes touching, they should be exactly the same height. This indicates the dice are symmetrical and will roll with even motion.

Look for dice made of high quality plastics. Dice made of cheap plastics will suffer from deterioration: edges break down, color changes, and over time become just as bad as tumbled dice. At Cons, vendors use lamps to make their dice look lustrous, often trying to hide the fact they are using cheaper plastic. Take the die out of the bright light and see if it still looks lustrous in regular light.

There are many online vendors now that sell precision dice, but do your research on their methods first. At the risk sounding like an advertisement, I consider Gamescience dice the best. Their dice with unpainted numbers are $1.50-$2.00 each. If you want the numbers painted for easy reading, there is an extra charge. An investment of 20 hand-painted dice will run you about $30.00, but it's well worth it.

You'll first need to determine how many you need. Unless you are Rich Uncle Pennybags, you will not need to replace every die in every game you own. What you need is a set of quality dice that you store separately and bring to the table when you play a game needing dice. So, find the game in your collection that needs the most dice and buy that many. For example, Grand Austria Hotel (2015) came with 14 garbage, wooden dice. Thus, I needed to buy 14 quality dice to play that game without feeling cheated.

One caveat are games like Castles of Burgundy (2011) and Pandemic: The Cure (2014) that have sets of differently colored dice. So not only will you need a minimum number of dice total, you'll need to make sure you have enough different colors to fit your games' requirements. For example, for Castles of Burgundy I needed 9 dice total: 2 green, 2 blue, 2 black, 2 red, and 1 white. However, because Grand Austria Hotel doesn't care what color dice you use, I didn't need to buy 14 dice for it, I only needed 5 more in addition to the 9 for Castles. Make sense? Doing an inventory of your games will help you decide what colors and how many dice you need (here is Google Doc you use to help you do it). Either make a copy to your Google Docs account or downloaded to use it locally. However, you'll quickly find you'll need/want a lot of dice, so make choices that fit your budget.

Finally, if your game has dice that have symbols on their faces instead of numbers or pips, don't worry, you can still replace them with numbered dice. You just need to assign a number to each symbol (or blank die face in some cases) so when you roll your quality dice the number it gives you can be mapped back to its releated sybole. See the example I put together for how I map my Star Wars: Rebellion dice. Note that each game die has two blank faces; therefore, I map the value of 5 to one blank and 6 to the other. Also notice that I don't use red-colored dice, I just use a color I already had.

A relatively new hobby is to make your own dice. Molds (usually silicon), resins and other equipment are readily available online. As a Maker, I fully support this. However, if you want fair and balanced dice, you have to follow some rules.

First, you will probably want a pressure pot to eliminate bubbles from your dice. As you can imagine, bubbles will drastically effect their balance. Also, while colorful and whimsical dice look cool, to be sure, they are unlikely to be fair dice. Differences in the density of different colored resins will cause imbalance. The pictured die has gold-leaf flakes in one corner and, while it looks very cool, the denser gold will cause it roll like traditionally loaded dice. Other things like glitter and other "impurities" will cause balance issues, too. Also, over polishing can result in inconsistent edges and corners.

Remember, it doesn't take much for a die to be sufficiently unbalanced to deny equal access to all sides.

For your games to be fair and balanced, you need proper randomization and it's critical that your dice are able to provide that. Your dice should grant you equal access to all of its faces. If they don't, you should seriously consider replacing them. Like I said, you don't need to replace very single die you own, but you should own a set of high-quality, durable, crisp-edged, balanced dice so that when you play a game requiring dice, you can use your good set instead of the cheap set provided by the publisher.

Happy gaming; happy rolling! Leave a comment letting me know what you think.

I've done a series of dice reviews on BGG which include both game dice and several "benchmark" reviews of dice made via industry standards.

Here is a detailed explanation of the review process I perform for each one.

Here is a GeekList of dice reviews for games I've posted on BGG.